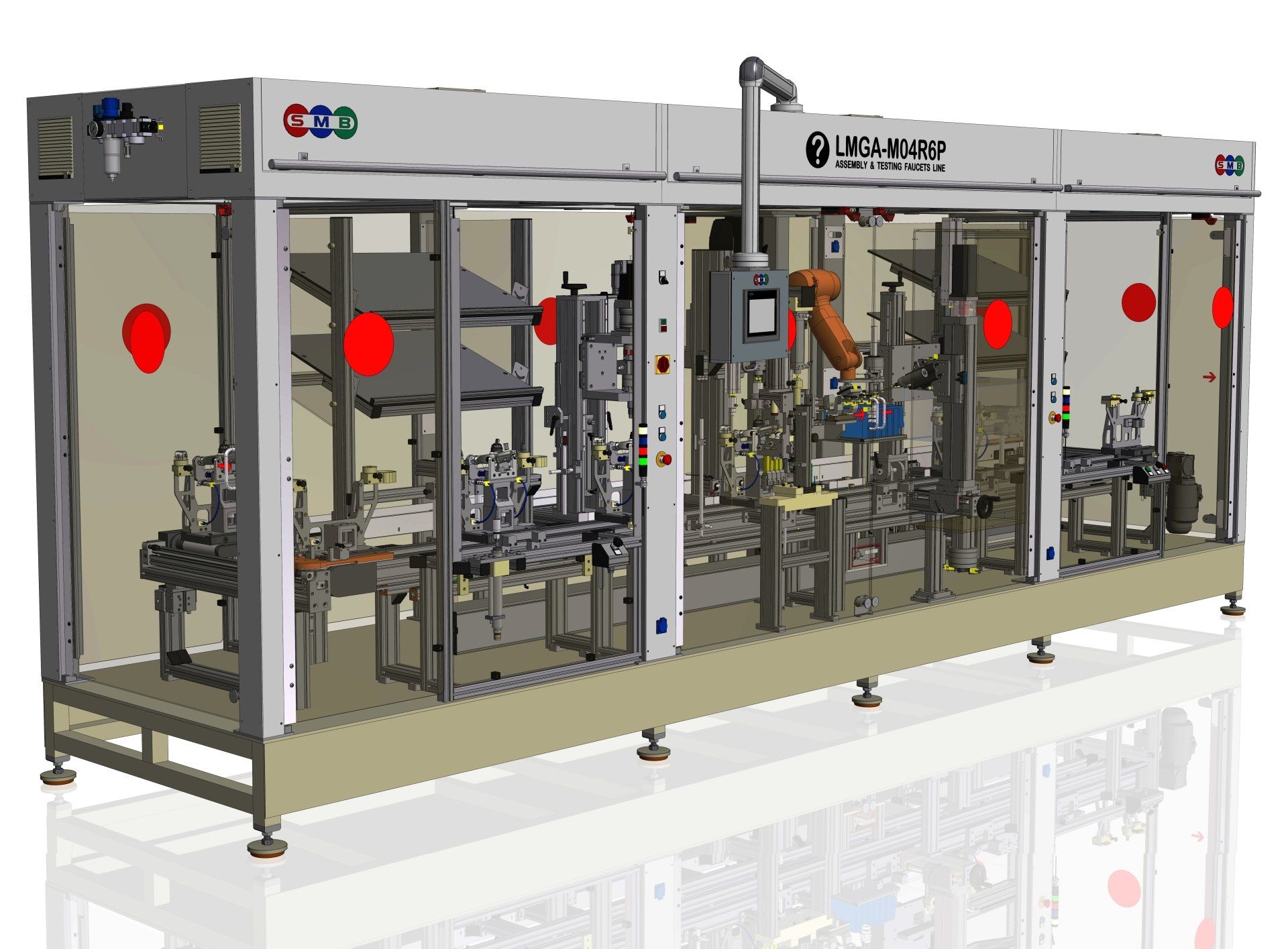

LMGA-M06R6E

Automatic Assembly, Verification and Laser Marking Line

AUTOMATIC ASSEMBLY, VERIFICATION AND LASER MARKING LINE

- The system is balanced for the assembly of countertop faucets with 2 operators 1 current table operator fitted. - Optimize the machine/operator/faucet model cycle. - The linear layout is designed to take up minimal space. - The cartridge nut is tightened using an electronic screwdriver with torque cell control. - We have one APE sealing station with a maximum 30-second test cycle in two closed and open phases. We have a 6-axis KUKA or ABB robot for the assembly of the cap, single-lever handle, and front tightening. A rear tightening unit is also included for single-lever handles. - Model changeover using transport pallets, interchangeable test fixtures, and parameterization of the assembly robot can be completed in 5 to 15 minutes, from one single-lever model to another. - The LASER marking system allows us to create logos and approval marks on the back of the body.

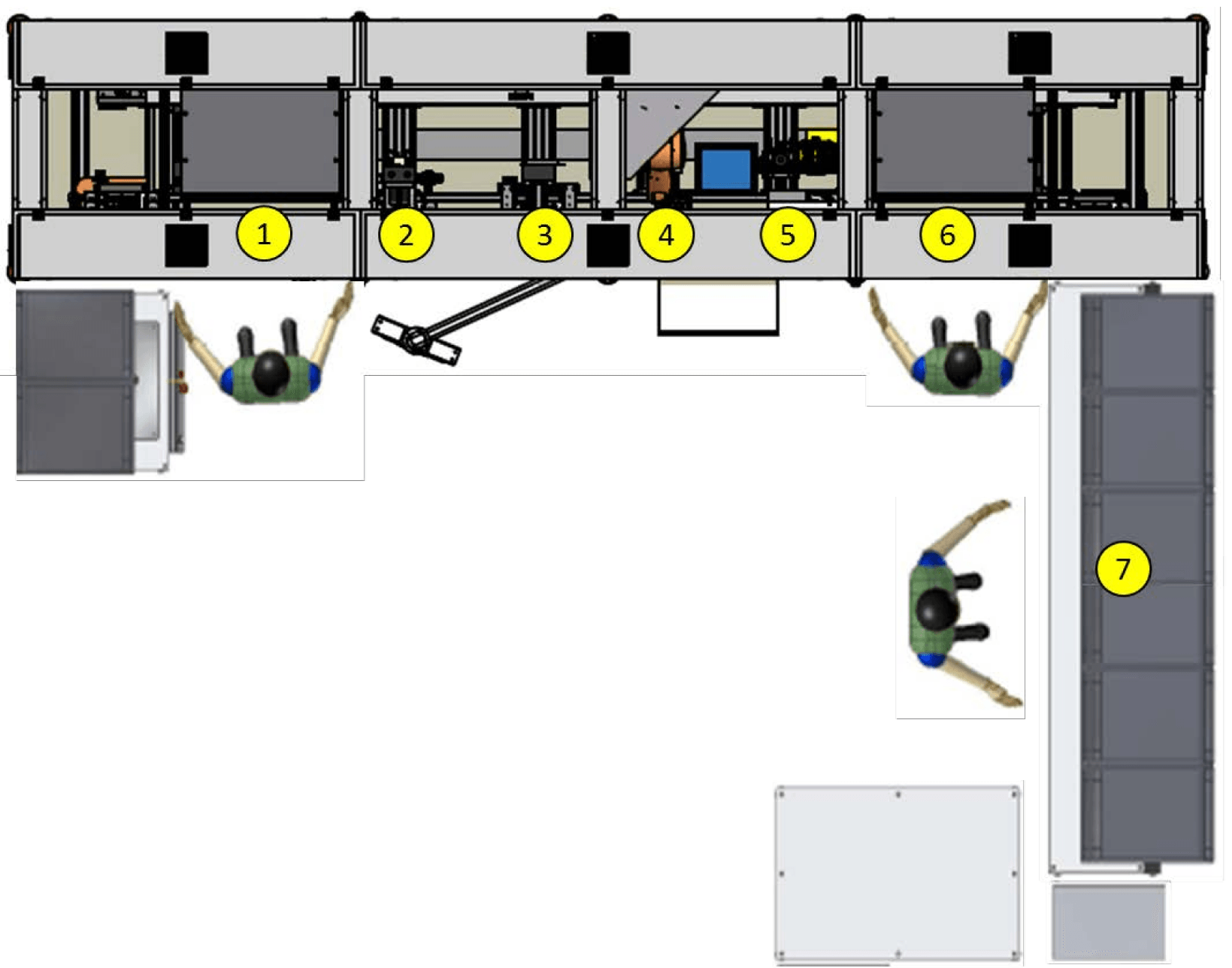

6-STATION AUTOMATIC LINE

1. Manual operator 1 station loading components Pre-assembly of washbasin, bidet and sink shelf Pre-assembly of batteries (seats fitting or diverter) 2. Screwing of cartridge nut with torque control 3. Test of closed cartridge tightness Test of open cartridge tightness 4. 6-axis robot: Assembly of hoods Assembly of single-lever handles Screwing of handles 5. Laser marking system 6. Manual operator 2 station (Aerator assembly and cleaning) 7. Manual operator 3 station (Packaging)

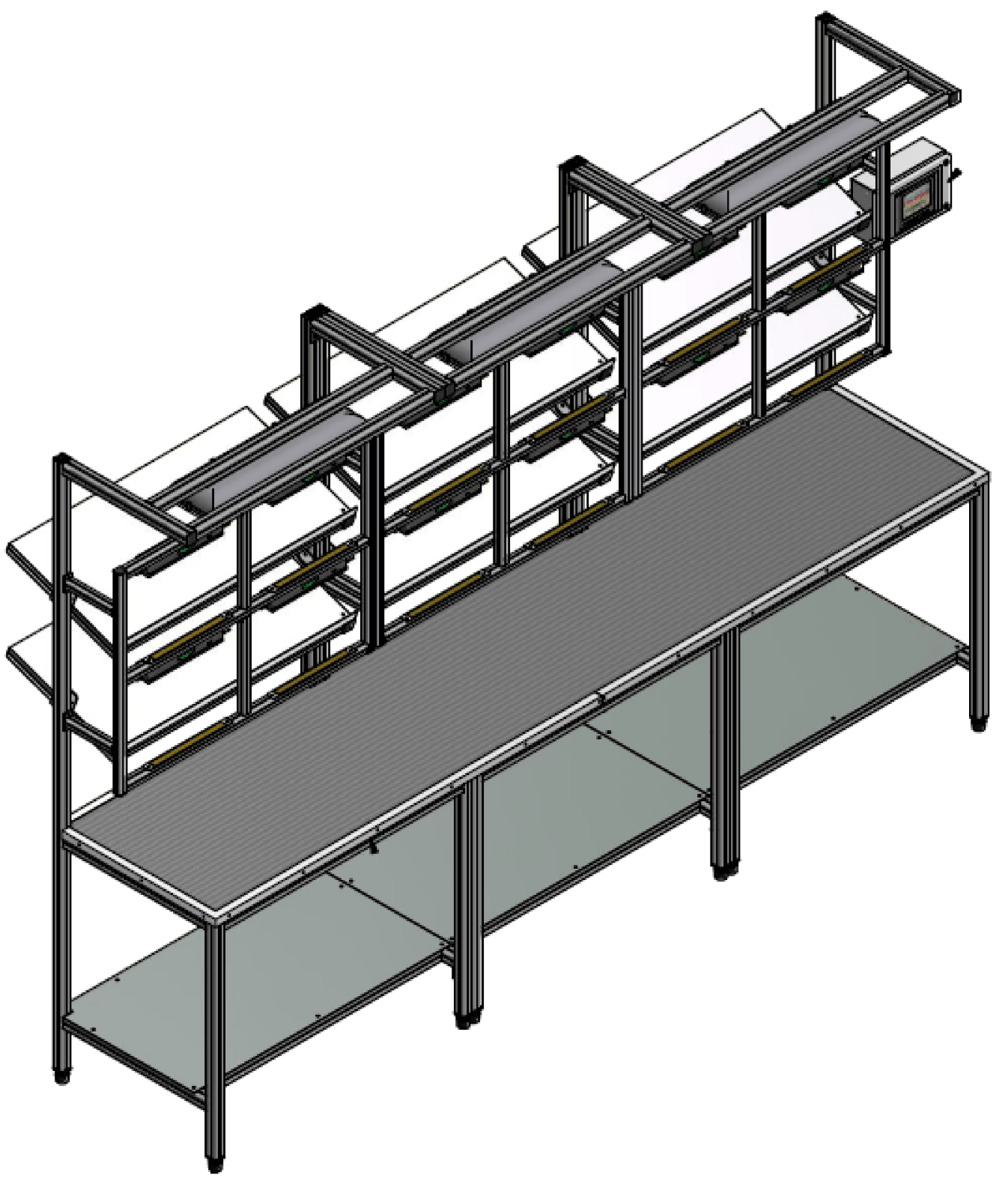

PACKING TABLE WITH POKA-YOKE

Structure built in aluminum profileOverall dimensions: Width = 3,000 mm Depth = 750 mm Height = 2,200 mm 6 Upper shelves with height and inclination adjustment.Electrical installation with protection systems for the connection of the different devices and integrated lightingCompressed air installation with filter regulator for the connection of all pneumatic elements. Wooden work base with rubber plate.Support and leveling feet with adjustment ± 20 mm.