APE MACHINE OPTIONAL ACCESSORIES

Electrolytic Labeling

The APE-6.7 can be equipped with an automatic part marking system for marking logos and/or approval marks with AENOR, NF, WIKA, ASME, etc. Once the leak test is complete (with a good part), the marking pad advances, creating the mark. The marking is achieved by circulating current (on chrome-plated material) through a screen printing process, using electrolytic liquid as a conductor. One of the keys to this machine's success is the ability to modify the parameters via the touch screen, making the marking lighter or darker.

SMED System

The SMED method is used in the context of tool changeovers on machines used in manufacturing. Its objective is to reduce changeover times, thus enabling a reduction in the minimum batch size. If series changeover times are reduced, the manufacturing process can begin. The goal is to reduce the time spent on setup, in order to achieve rapid tool changes or even instant setups.

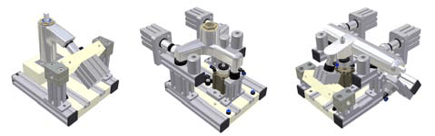

QUICK TOOL CHANGE

Every APE-6,7 containing multiple tools has the option of incorporating a quick-change tool (clamp tool). This consists of a fixing system without screws or knobs. This ensures that each tool change is performed quickly and reliably. The system incorporates a connection at the base of the tool, which is coupled to the quick-change connector located on the APE-6 base plate.

QUICK CHANGE OF PRESSERS

The new APE-6 models feature a new quick-change system. A retractable positioner has been added to the standard clamps so clamp changes can be completed in approximately 2-3 seconds.

Interchangeable Tooling

The design study is carried out individually, taking into account the size and behavior of the part to be tested to maximize the test's efficiency. All equipment is designed on a plastic base plate. Pneumatic cylinders push a sealed plug, thus blocking the part's outlet. Nozzles are fitted to the inlet, and the tap is sealed, allowing the leak test to begin.